Coke production – Control activities of Thermal division

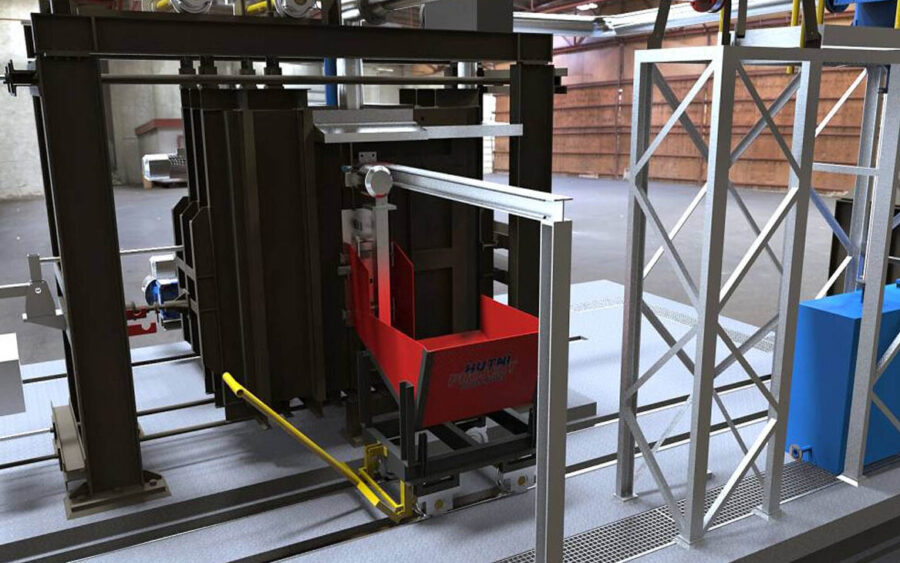

Category: Coke Location: Trinec Client: Trinecke Zelezarny a.s. Type of construction: Revamping and modernization Implementation: 2017 Description: Company HUTNI PROJEKT Frydek-Mistek a.s. provides within this project activity thermal control for the construction and start-up activities associated with the COB no. 11.